KUNJU Machine-Disposable Medical Product & Industrial Sewing Machine Producer.

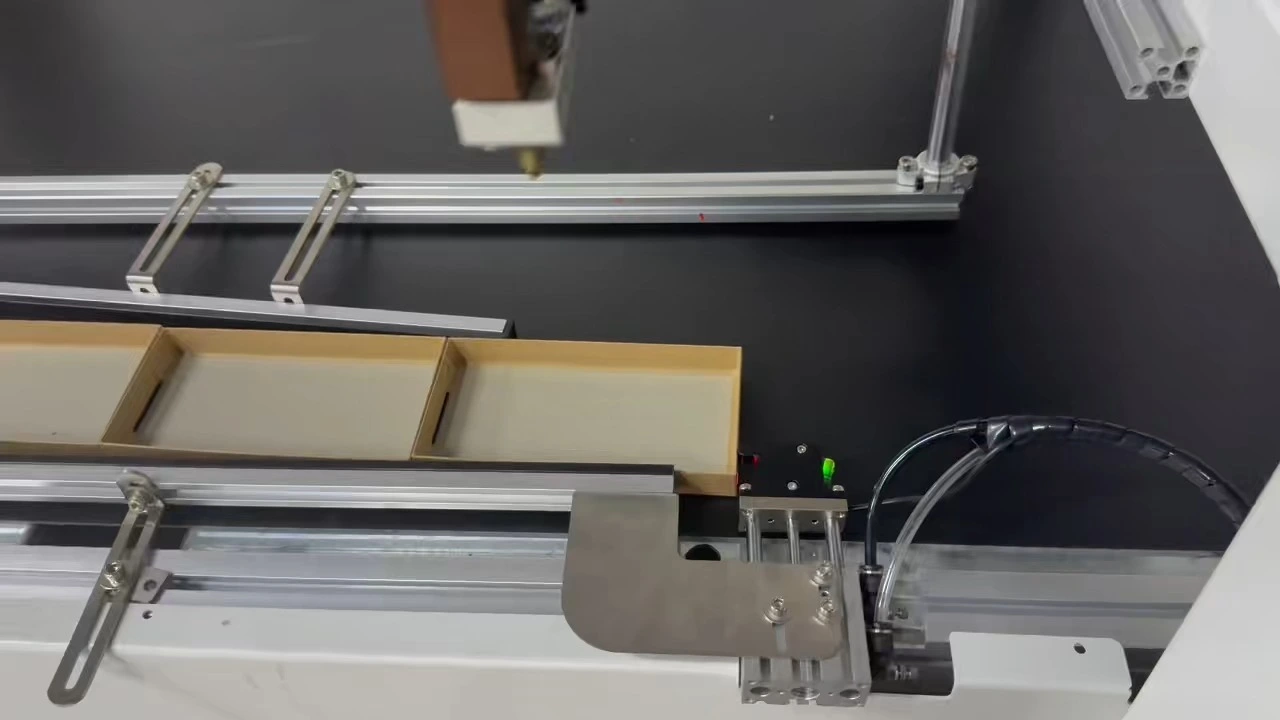

KJ-0605 On-line Glue & Adhesive Spraying Production Line

Introduction:

Connected intelligent glue spraying machine, with built-in assembly line design, can seamlessly connect front-end and back-end equipment to build a complete automated production line.

After the products produced by the front-end equipment automatically flow in, the machine senses the products and starts automatic glue spraying. After completion, the products are automatically transported to the back-end, achieving unmanned operation of the entire process from feeding, glue spraying to discharging

Application:

Printing packaging, cosmetics, electronic products etc.

Advantage:

Printing Packaging & Cosmetics & Electronic Products Adhesive Spraying Machine supports flexible combination and docking, easily adapts to various production line layouts, greatly improves the level of assembly automation, effectively replaces manual labor, and efficiently meets the needs of batch spraying operations.

Parameter:

| Model | KJ-0605 |

| Machine size | 1800x1000x1400mm |

| Working scope | 600x500mm |

| Conveying belt size | 1800x650mm |

| Operating system | 4 axis motion control system |

| Working accuracy | ±0.5mm |

| Machine characteristics | flat spraying, strip spraying, 360°rotating spray glue |

| Function | 4-axis operating structure: 90°, 45°, 0°side and bottom for gluing |

| Motor configuration | X,Y, Z axis controlled by Inovance servo motor |

| Working power | ±3KW |

| Applied glue | hot melt glue |

| Running speed | 10-800mm/S |

| Adhesive tank | 5L touching screen hot melt glue machine |

| Gas source demand | 0.1-0.6Mpa |

| Voltage | 220V, 50Hz |

| Weight | 220kg |

Add: 1209E4, International Chamber of Commerce Center, 168 Fuhua 3rd Road, Fu'an Community, Futian Street, Futian District, Shenzhen, China